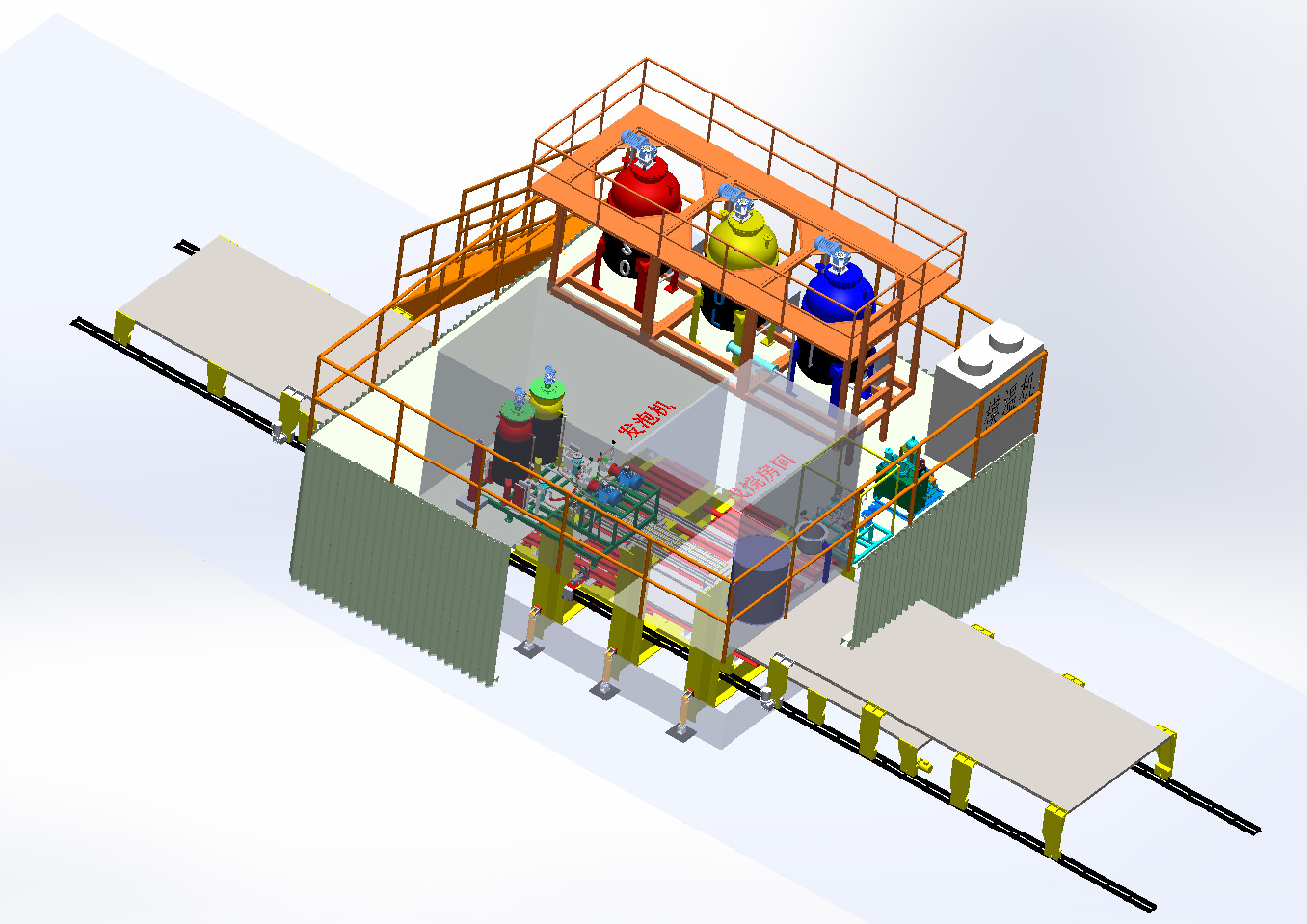

2 + 2 tilting laminating machine

The size of discontinuous polyurethane sandwich panel/refrigerated carriage panel production equipment reaches 3.5 m x 14 m, adopts double-side in and out form, the host can tilt; At present, it is the most advanced large-scale special equipment for hot-bonding and pressing of compound panel of Van Van, which can produce cold storage panel and large-scale panel. The equipment is composed of main frame, left and right moving conveying platform, carrying template, hydraulic driving lifting platform, hot pressing plate heating system, PLC control system, etc. .