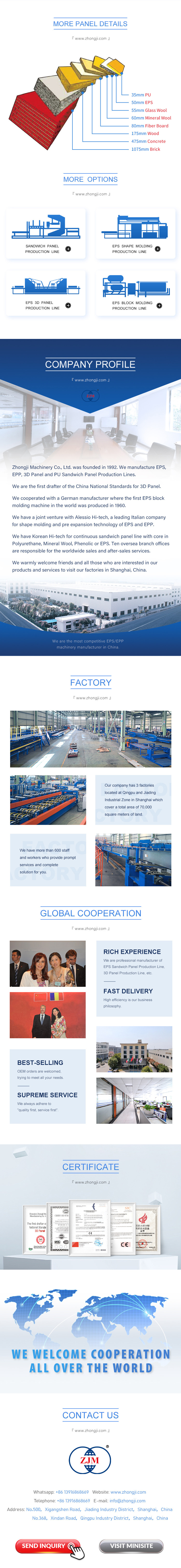

Cooling System

Cooling system is one of the important links of sandwich panel production line, when customers want to produce PU panels, this kind of cooling conveyor is necessary. This cooling device can cool the PU board during the production process.