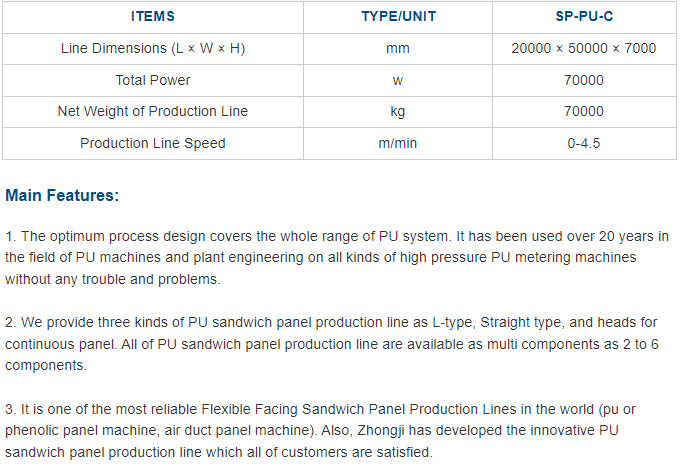

Cutting unit by Disk saw

The perfect cutting unit has to have the cutting speed is synchronized with the panel conveying speed.

This cutting unit has to be also operated by the manual or automatic control.

Cutting unit by Disk saw

The perfect cutting unit has to have the cutting speed is synchronized with the panel conveying speed.

This cutting unit has to be also operated by the manual or automatic control.

Main feature:

The perfect cutting unit has to have the cutting speed is synchronized with the panel conveying speed.

This cutting unit has to be also operated by the manual or automatic control.

The gantry is set at the rear and the saw unit is positioned at the right-hand side as viewed from direction of production.

The double belt line conveys panel at a pre-adjusted speed.

An incremental encoder is installed at the turning shaft of the double belt measures the length of the endless panel.

The pulses are transferred to the microprocessor control of saw.

The saw waits for the start signal depending on the panel length and then

accelerates the X-axle to maximum speed so that the speeds of the endless panel and saw are equal.

After synchronization of both speeds and offset control, the clamping units are

pneumatically actuated to clamp the front and back of panel and then saw

carries out the first cut from left to right front direction (traversing).

The cut panel is lying on a non-driven roller conveyor and is pushed out of the operating area of knife by the panel coming from behind.

Saw unit returns to the starting position at a maximum speed.

At this position saw waits for the next start signal (depending on the length of the sandwich panel) and the above described procedure starts again.

Operating panel is equipped out of housing and Panel can be automatically cut without worker in case the data of panel length and quantity.

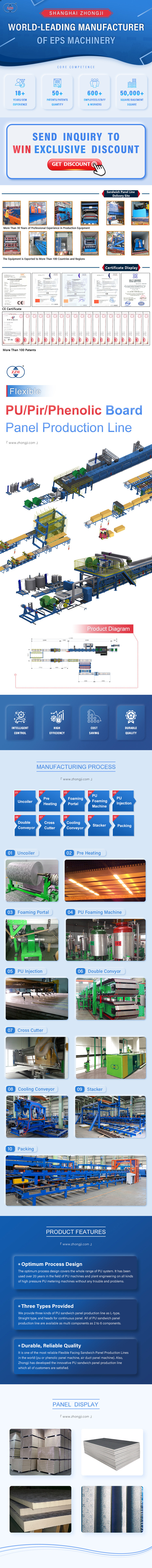

Technical parameters:

| Type | Cutting type by disk saw (Traveling guide bar : Approx. 5 meter) | |

| Knife quantity | 1 set | |

| Cutting times | Max. 4 times/ min | |

| Watt | Approx. 20kw | |

| Knife unit | |||

| Cutting speed | Max. 100 m/min., infinitely adjustable | ||

| Cutting width | Max. 1,300mm | ||

| Cutting thickness | 10~100mm | ||

| Length of Knife | Approx. 100mm | ||

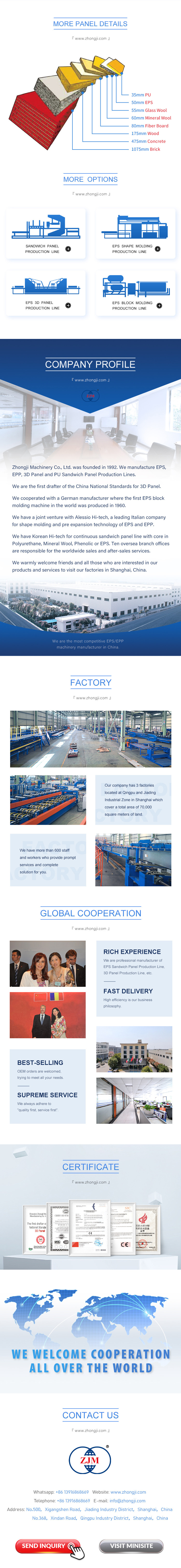

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 50 items.

Online Message

Reminder: In order to get in touch with you in time, please be sure to fill in your contact information and demand information completely. You can enter your demand, such as the model of the product, testing materials, and the budget range of the product; you can also use your mobile phone Call our account manager.