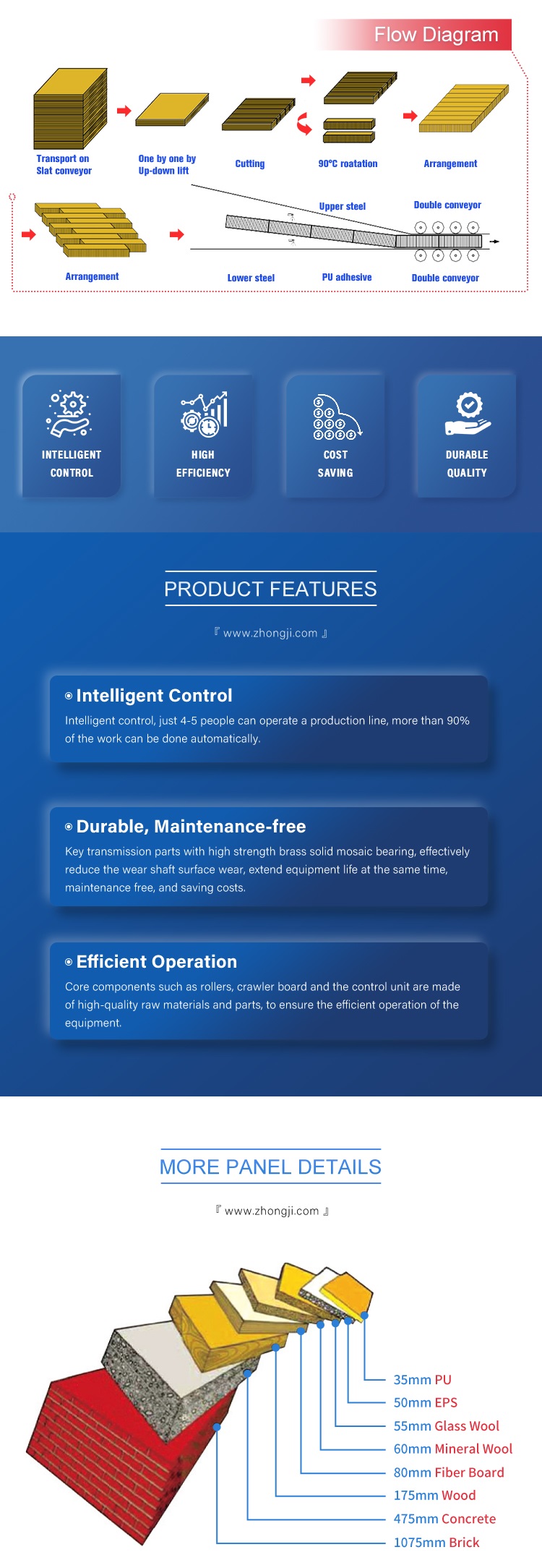

Building material board glue machine

The machine is used in building materials, furniture, textile, automobile, sports equipment and other industries. Main application: aluminum honeycomb board, Heat Preservation Board, decorative board, aluminum corrugated board, stone honeycomb board and other building materials industry automatic spraying.