High pressure machine

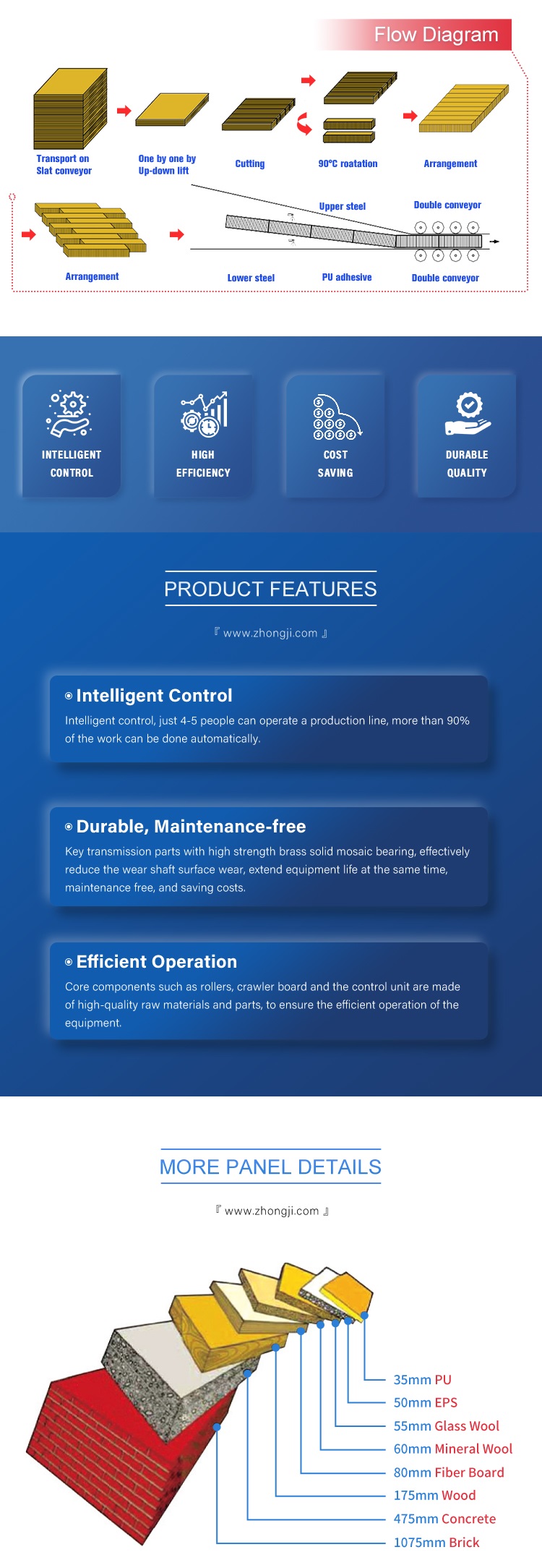

The high pressure machine is composed of the main engine, the hydraulic drive system, the iron conveyor belt carrier formwork, the carrier formwork bracket, the carrier formwork heating system, and the electric control system.

High pressure machine

The high pressure machine is composed of the main engine, the hydraulic drive system, the iron conveyor belt carrier formwork, the carrier formwork bracket, the carrier formwork heating system, and the electric control system.

Main feature:

1. The composition of the equipment: the equipment includes a gantry frame, a support frame, a base, two belt-type loading templates, a guide rail, an electric control cabinet, a hydraulic system, etc.

(1) Host: The host consists of a frame, a lifting beam, and a base.

(2) Hydraulic drive system: The hydraulic drive system consists of a hydraulic station, 16 lifting cylinders, a set of pressure-maintaining pumps, and corresponding high-pressure oil pipes and valves.

(3) Specifications of the loading formwork: length 12.5m, width 2.5m, thickness 100mm, composed of welded steel plates with belts attached to the surface. There are 2 loading templates, both of which are belt type.

(4) Loading formwork heating system: Loading formwork heating system consists of oil medium heating device, pump set, pipeline and corresponding temperature control device.

(5) Electric control system: The electric control system is centrally controlled by the electric control cabinet, equipped with corresponding buttons, relays, temperature controllers, etc.

(6) Security system.

2. Press action interlock protection: hydraulic action interlock, hydraulic overpressure limit, low pressure automatic compensation, automatic loading and unloading platen limit.

3. There are emergency stop switches around the press.

4. There is an alarm light flashing when the movable platen goes in and out of the press.

Technical parameter:

| Product thickness specification | 50~150mm |

| Template size | 12500×3200mm(including movable track shoes and upper and lower fixed template) 0.5mm Teflon belt on the surface of the upper template 3mm belt on the surface of the lower template |

| Template surface flatness | ≤0.5mm/m2((template surface in contact with workpiece) |

| Overall clearance after the upper/lower formwork is closed | ≤0.5mm/m2 |

| Surface roughness | Ra∠6.3um |

| Working height of mobile carrier formwork | 700mm |

| Mould opening height | 200mm |

| Equipment maximum clamping pressure: | 300T |

| Closing time | 45s |

| Clamping hydraulic plunger cylinder | ¢100mm |

| Hydraulic station motor power | 15kw |

| Maximum hydraulic pressure | 20 MPa |

| Voltage: | 50HZ、380V |

| Power supply | four-wire three-phase AV380V, 50Hz |

| Control method | PLC control |

| Working height of mobile carrier template | 700mm |

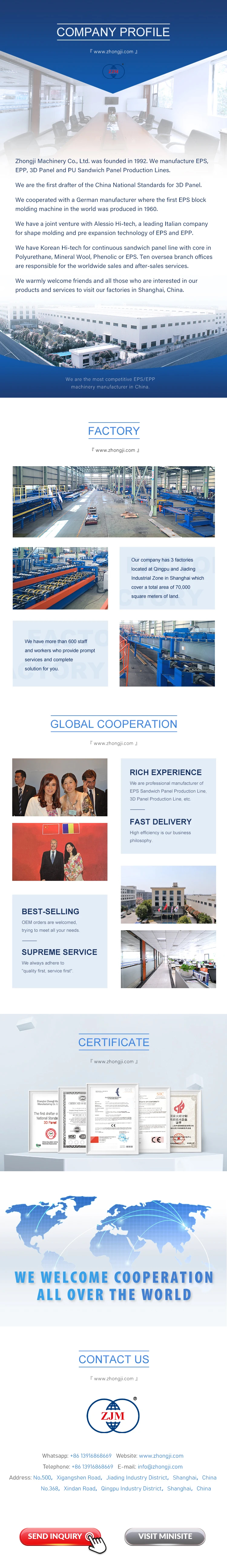

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 50 items.

Online Message

Reminder: In order to get in touch with you in time, please be sure to fill in your contact information and demand information completely. You can enter your demand, such as the model of the product, testing materials, and the budget range of the product; you can also use your mobile phone Call our account manager.