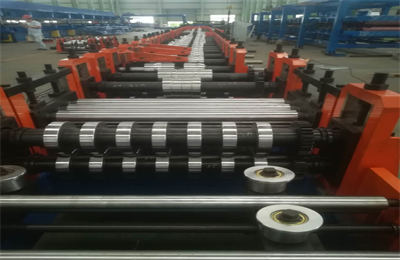

Double layer roll forming machine

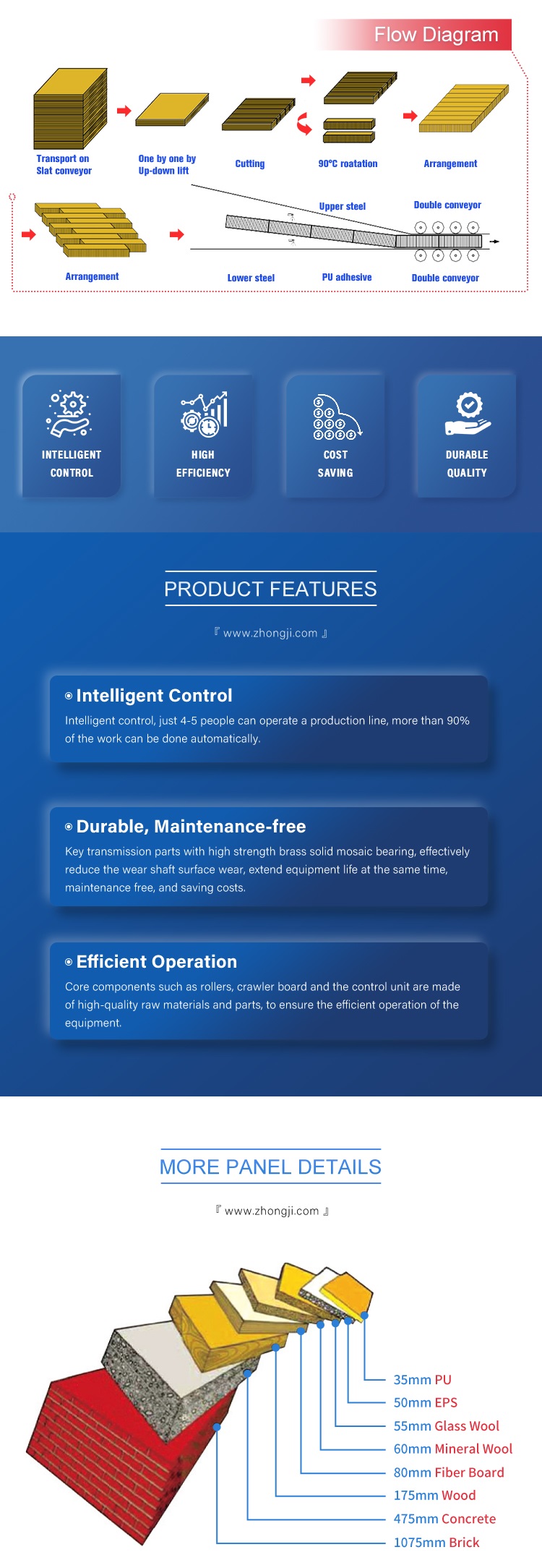

The double-layer roll forming machine is composed of manual feeding device, leveling device, transmission device, forming roller table and host (including guiding platform), cutting device, hydraulic system, electric control system, finished product suppo