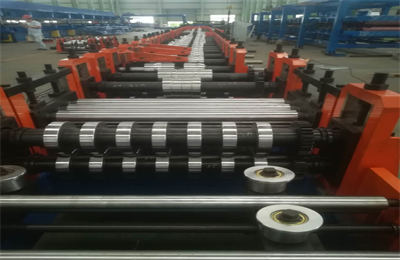

Double layer packing box roll forming machine

The roll forming machine is made of high-quality bearing steel GCr15, quenched at 58-62 degrees. After direct quenching, the surface is finished without other treatment. The control system adopts Siemens PLC control system, and the cutting method adopts